Chain

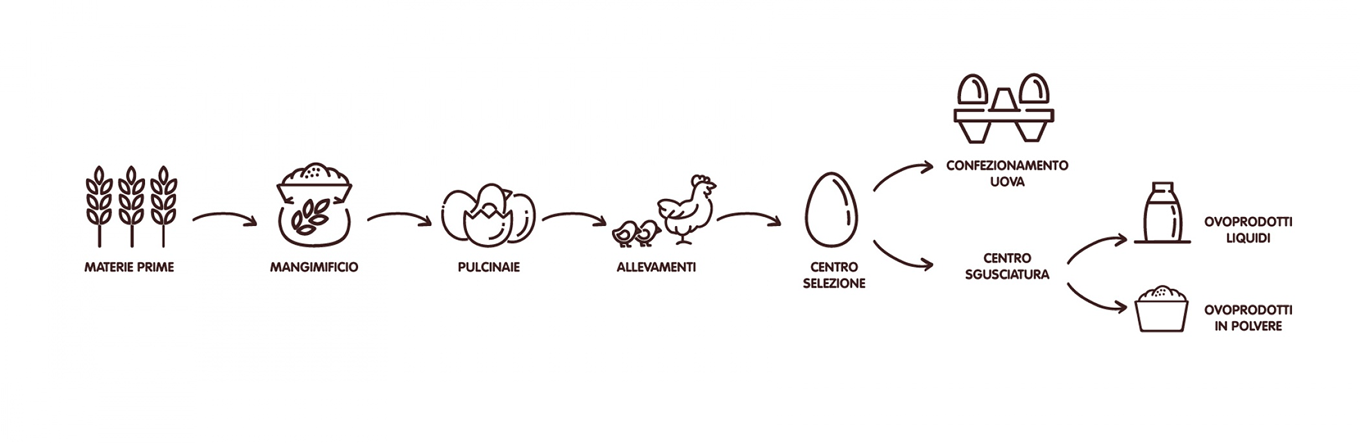

Eurovo's entire production process, from the selection of raw materials to feed the hens to the delivery of finished products, is developed within a supply chain fully managed by the Group.

This integrated model represents one of Eurovo's main strengths, because it allows direct and constant control over each production stage, guaranteeing quality, safety and transparency.

Eurovo's agrifood supply chain is vertically integrated and subject to rigorous controls at every step: more than one million analyses are carried out each year, from chick to finished product.

Continuous monitoring, combined with technological innovation and constant plant modernization, ensures high standards of food safety and traceability.

From the simple egg in shell to egg products destined for industry, Eurovo's strength lies in its ability to manage the entire production chain in-house, guaranteeing speed, reliability and consistent quality.

The Group's commitment also extends to sustainability and animal welfare. Through its agricultural companies and research projects, Eurovo promotes increasingly responsible and sustainable production practices to build a transparent, innovative and future-oriented supply chain model.

The heart of the supply chain are the farms

The heart of the supply chain are the farms, managed with attention to animal welfare and compliance with the strictest regulations. Each hen is raised under controlled conditions, with protocols aimed at ensuring the health, safety and quality of the eggs produced.

Eurovo has its own feed mills

To ensure balanced and safe nutrition, Eurovo has its own feed mills. Here, selected feeds are produced and formulated according to strict standards to ensure optimal nutrition and total control over the quality of raw materials.

From farms, eggs arrive at processing plants

From the farms, the eggs arrive at the processing plants, where they are sorted, packaged or processed into egg products for domestic and professional markets. State-of-the-art technologies and constant controls ensure freshness, safety and traceability in every batch.

The farms represent the first link in Eurovo's integrated supply chain and are the starting point for ensuring quality and safety throughout the production process.